Safety and Convenience: MC4 Connectors for Solar Cables

Connecting lines carrying direct current (DC) is more challenging and dangerous than connecting lines carrying alternating current (AC). To make matters worse, solar energy systems require making custom lines lengths and connections at awkward places like roofs, lofts, under panels, etc. MC4 connectors ease these problems. They are specially designed for fast and safe work and mitigate the risks of connecting DC lines.

In This Article:

What Are MC4 Connectors?

MC4 or MC4-type connectors are electrical connectors used for extending a PV cables or connecting to endpoints such as junction boxes, solar panels or inverters.

Clearly Identifiable Polarity

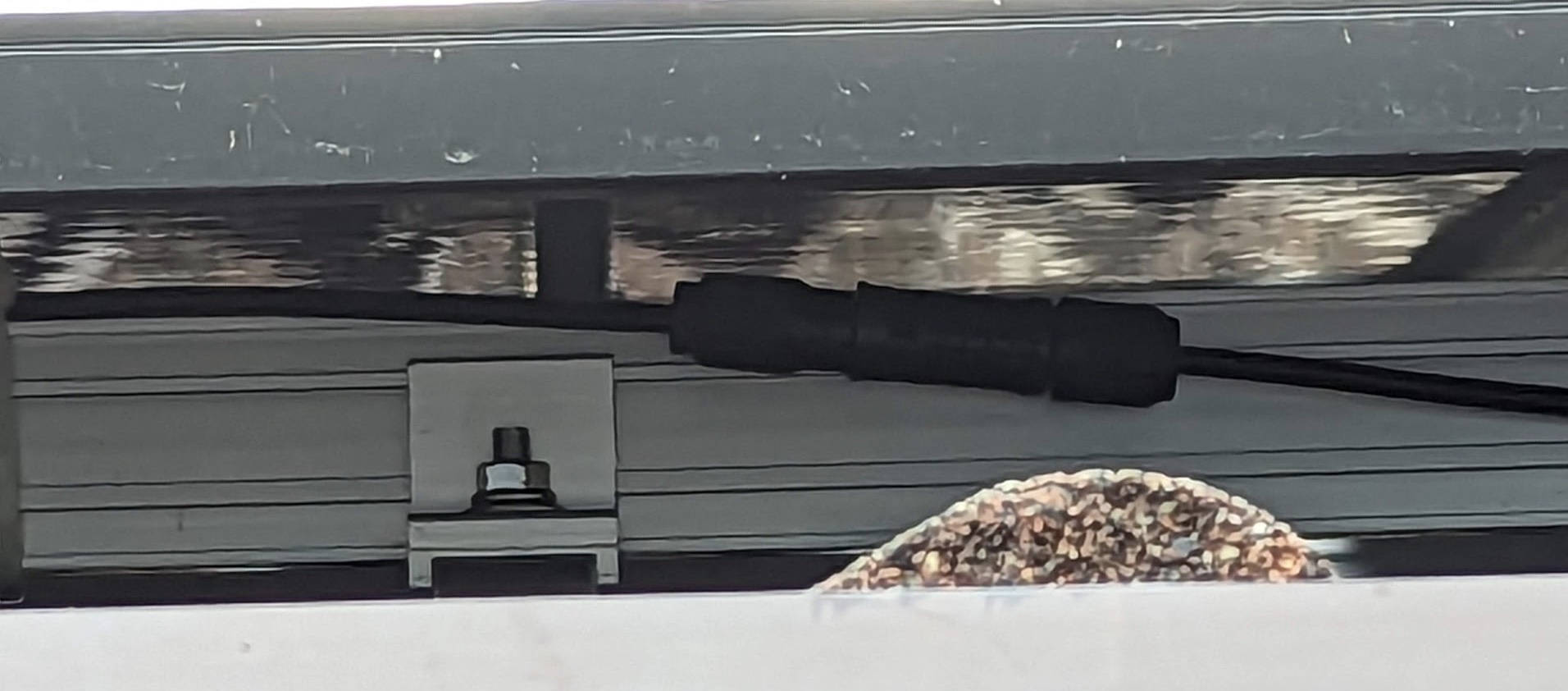

An MC4 connector consists of male and female sides that clip to each other. Sides are designed with polarity in mind. Usually, the male side is expected to carry the positive pole, and the female side carries the negative pole. The sides have sturdy plastic housing. It is made of extremely low conductive plastic compounds to protect the electric cables inside them from the elements and contact with conductive surfaces or humans.

How Do MC4 Connectors Work?

An MC4 connector connects two cables via metal inserts which are part of each side of the MC4 connector. The metal inserts are crimped to the cables with specialised crimping pliers to guarantee a firm grip and secure contact. They are also isolated in plastic elements that clip to each other.

Strong Contact and Polarity of the Metal Inserts

The metal inserts slot into each other and are also called male and female inserts. The metal inserts are housed in the plastic elements of the Mc4 connector, which are designed to clip to each other and hold fast.

Male Metal Inserts Are Housed in the Female Plastic Clip

The polarity association in metal inserts is opposite to the housing. The male metal insert carries the negative pole, and the female insert carries the positive pole. The metal inserts utilise a snug fit to maximise the contact surface when connected.

Clipping Mechanism for Strong and Safe Connection

The clips are hard to unclip even when intended, thus guaranteeing constant contact between the metal inserts and guarding against unintentional disconnection. The plastic housings have cable glands to prevent water from entering the connector and contacting the cables.

Safety Advice

An adequate constant contact surface helps prevent sparks from appearing in cases of cable movement. Do not disconnect MC4 connectors on live wires. This will result in a spark.

Why Do We Need MC4 Connectors?

The role of an MC4 connector is to connect cables safely and easily.

Safer Against Sparks as DC Increases That Risk

Connecting cables carrying DC is more complex due to the nature of the current. DC is constant, whereas AC goes from peak through 0 around 50 times in a second. Therefore, providing some chance for sparks to break or for humans suffering electric shock to release from it. Electric sparks produced by DC will remain unbroken, generating heat and posing a fire hazard. These sparks are extremely hot and resilient that they are used for welding metals such as steel.

Convenience of Use and Speed of Work

Working with solar energy equipment requires electrical connections to be created in challenging and awkward places. For example, at the back of solar panels or around building features.

This demands an easy way to make such connections safely, and the MC4 connector is designed with that ease of work in mind.

Internation Safety Standards Covered

Reputable MC4 manufacturers produce MC4 connectors complying with the following safety standards:

- TUV Certification: TUV is a German certification that signifies a product has been tested for safety and meets the minimum requirements of German and European directives. See here for an example of a certified manufacturer’s certificate verification:

- UL6703: This is the standard for plug connectors for use in photovoltaic systems from Underwriters Laboratories (UL) in the USA.

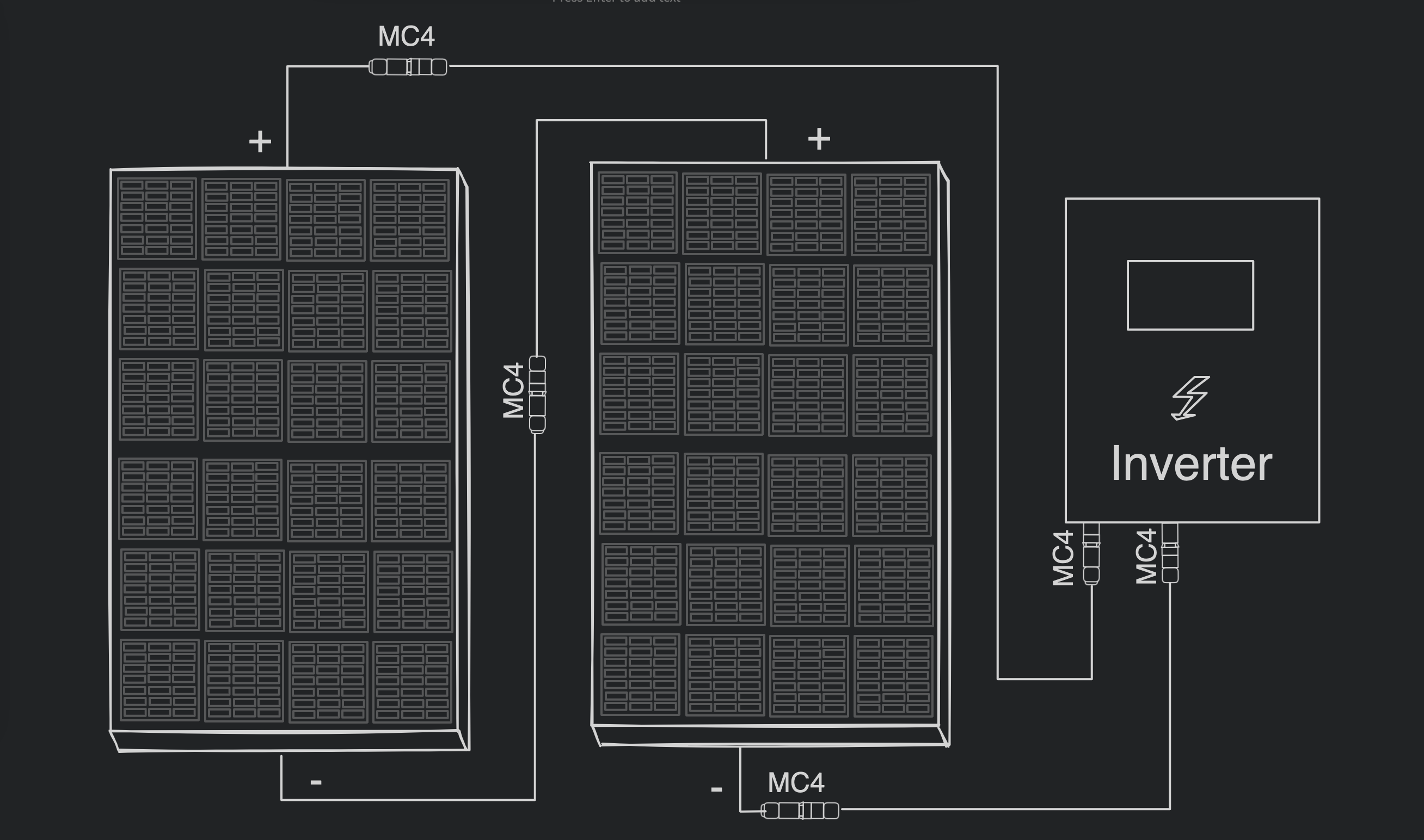

How Are MC4 Connectors Used in Solar Energy Systems?

MC4 connectors are typically used on solar panels, inverters, micro-inverters and optimisers. These come pre-fitted on the equipment, ready to connect to your installation. Most of the time, MC4 connectors are assembled and crimped to cables as and when required during the solar energy system installation.

The ease of work and the safety features provided by the MC4 extend their usage in other places. For example, junction connectors for parallel connection of solar panels use MC4 type connectors with multiple male or female ends and a single opposite end for connecting to the next line.

Conclusion

MC4 connectors stand out for their reliability, durability, and ease of connection, making them an indispensable choice for solar installations. Their design ensures a tight and secure connection, minimising the risk of disconnection or power loss. By opting for MC4 connectors, homeowners and installers can enjoy a seamless, safe, and effective solar energy system setup.

Did you like this article? Would you like to share your feedback? Head over to Solar Energy Concepts, where you can talk about this article and share your thoughts.

Back to TopSee Also

Solar String Expansion. Panels Connection Parallel vs Series

Solar String Expansion. Panels Connection Parallel vs Series

The Critical Role of Solar Inverters in Energy Conversion

The Critical Role of Solar Inverters in Energy Conversion

Best Angle For Solar Panels and Optimal Roof Direction

Best Angle For Solar Panels and Optimal Roof Direction

Solar Panel Guide: Size, Electricity Generation, and Output

Solar Panel Guide: Size, Electricity Generation, and Output

Wall Mounted and Vertical Solar Panels Installation Guide

Wall Mounted and Vertical Solar Panels Installation Guide

Rooftop Solar Panels Install Guide: Equipment, Tools & Tips

Rooftop Solar Panels Install Guide: Equipment, Tools & Tips

Maximising Solar Power Harvest With Overpaneling

Maximising Solar Power Harvest With Overpaneling